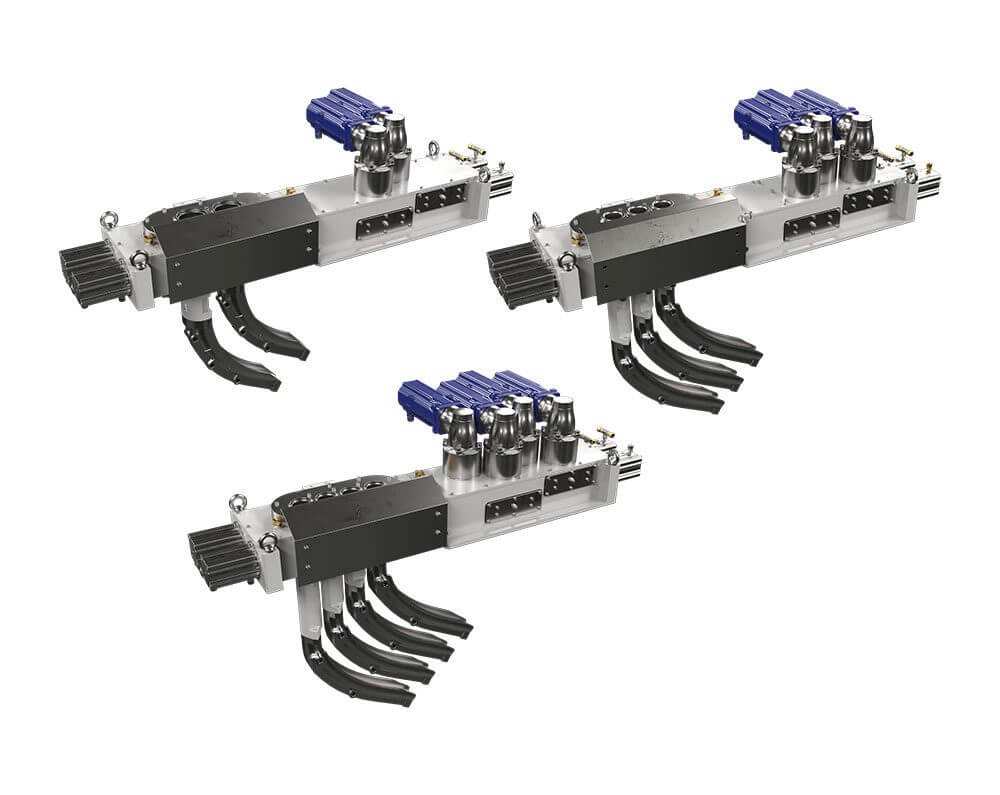

Multi Direct Drive X2/X3/X4

For a fast and precise gob delivery

Main Data

• Max. Speed = 240 cuts/min

• Min. motion time = 100 msec

• Min. waiting time = 150 msec

• Max. jump = 64°

Benefit

• Electronic independent position control for each scoop

• Possibility to align independently each scoop with trough

• Great improvement of gobs delivery on high production machines with multigobs delivery equipment

• High rigidity and low inertia for high performances

• Very low vibrations at high speed

• High dynamic response

Technical Features

• Interchangeable with the previous version

• Motion control with independent electronic cams per gob

• Emergency with stand-by position out of the glass flow

• Controlled by electronic integrated or stand-alone system

• Interface with any type of machine;

• Programming of the data by operator’s computer or hand-terminal

• Easy and efficient trouble diagnostic

• Local control panel with start, stop, manual MODE, jog, emergency, hand terminal connector

Mechanism Description

• Motion control with independent brushless motors for each scoop

• Coaxial planetary gearbox for each motor

• Direct drive system with pinion-rack for each scoop

• Pinions, racks and guides all in oil (scoop holder too)

• Pneumatic cylinders for the emergency central positioning

• Proximity switch for the control of the working position

• The mechanism, controlled by a pneumatic cylinder, has the possibility to rotate of 22° to put it in emergency position

• Motor cooling with fan air

Do you need a custom accessory?

Contact usForming Machines

The internal R&D Department is focused every day on finding the best solutions to be applied in IS Machines which not only allow the production of perfect glass containers, but also a high performance production, reducing costs.