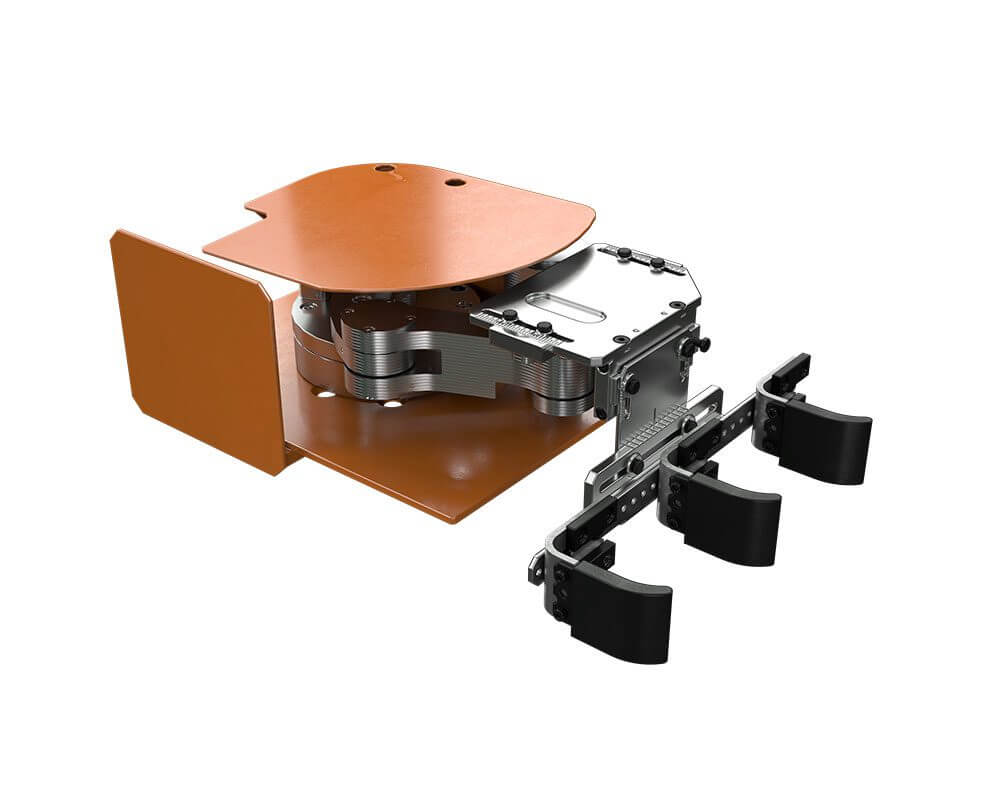

Pusher

AP Pusher

to move bottles from the IS Machine to the Conveyor

Main data

- Controlled by two coaxial torque motors

- Max conveyor speed = 50 m/min

- Articulated pentalateral linkage for the fingers control

- Control with 3 degrees of freedom on the fingers

- Available for all machines and conveyor types

- SG – DG – TG – QG

Benefits

- No belt transmission or reduction-gear on the drive but only linkage system for a very reliable mechanism

- Low inertia high rigidity design

- Accurate wares handling with the possibility to adjust the angular and axial positioning of the wares on the conveyor

- Very good performances on high speed conveyors

- High flexibility with the cam generator

Mechanical features

- Motors and linkage in alluminum alloy

- Integrated or stand alone control with the possibility of easy synchronization with no BDF IS forming machines

- Use of digital drives and brushless torque servo motors

- Possibility to easily modify the cam parameters from the machine computer

- Cam Generator Software to make

Do you need a custom accessory?

Contact usForming Machines

The internal R&D Department is focused every day on finding the best solutions to be applied in IS Machines which not only allow the production of perfect glass containers, but also a high performance production, reducing costs.