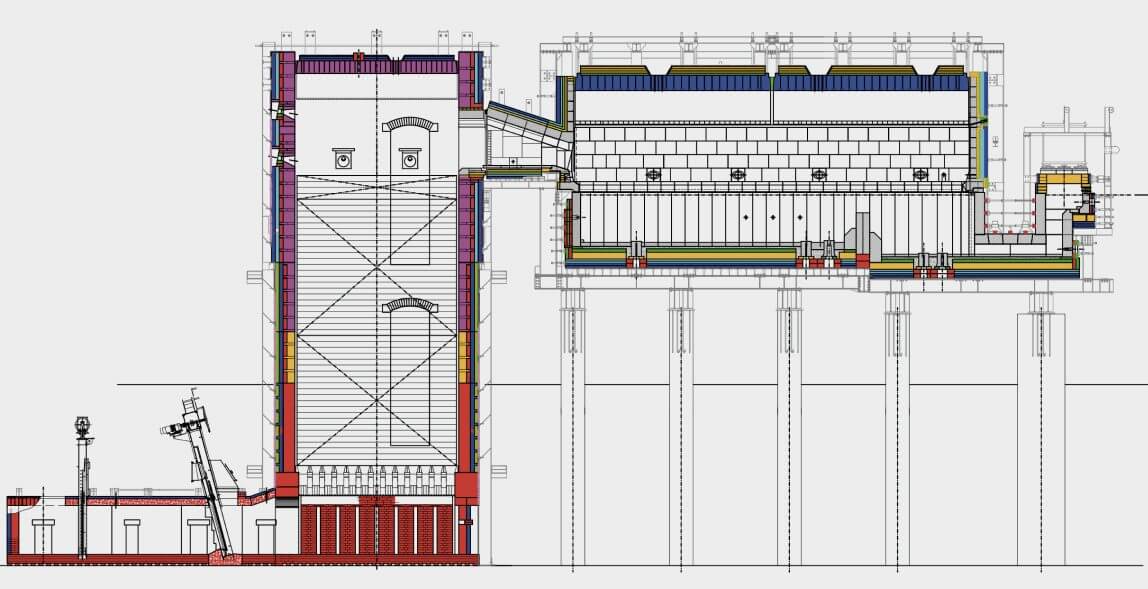

Regenerative & recuperative furnace

Technical sheetThe expertise acquired throughout the years and the big number of efficient plants installed allow BDF Industries to offer new and innovative solutions when it comes to implementing plant engineering projects. Not only does our Group supply turn-key plant solutions, but our commitment and responsibility is from the beginning to the stage we are there to start the plant ourselves.

Following the tot process from initial melting to final shape of the article.

- Low furnace energy consumption

- High furnace pull

- Low NOx emissions

- High furnace lifetime in terms of metric tons/m2

- Best furnace operation to assure minimum operating costs at fixed glass quality

- Energy flexibility

- CO2 reduction

- Easy and ergonomic scada supervison

Regenerative

In end-fired Regenerative Furnace, air preheating is achieved by two regenerators chambers. The regenerators are filled with layers of refractory checkers, arranged in offset position. The exhaust from the furnace and the cold combustion air are passed, alternately, through one and other system for a certain period of time. The checkers, heated by hot waste gases, releases the accumulated heat allowing to reach a high temperature to the combustion air without using additional fuel.

OXYFUEL

OXYFUEL

Save on regenerator CAPEX and convert your combustion to oxy-fuel. This type of furnace allows you to avoid heat recovery, streamline the combustion process, and utilize all the downstream heat. More over gives you an advantage on terms of NOx emission.

Recuperative

Recuperative

In Recuperative Furnace, air preheating is achieved by the heat exchange from the exhaust to the combustion air by means of metal recuperator. The exhaust pass through a metal heat exchanger and transmit the heat to the combustion air. The preheated air is conveyed to the burner by metallic ducts, where it matches the fuel developing the flame.

Flex-EF

The key word for this solution is FLEXIBILITY. To reduce the impact of rising fuel costs or CO2 emissions, BDF offers an unconventional regenerative furnace with a mix of energy sources: electricity up to 40%, oxy-fuel, hydrogen, and air-gas combustion. All tailored to the specific characteristics of your system. HFO or diesel combustion systems can also be installed to provide greater flexibility to your furnace. A special arrengement allows also the regenerators to follow drastic reduction in flue flow rats.

Hybrid

While we wait for reliable and affordable hydrogen, our pioneering hybrid vision is one of the solutions to reduce CO2 emissions. Our solution is the horizontal hybrid electric fuser. Our concept has been tested through seven years of simulation and design: come and experience the results.

Full Electric

Complete electric melting to be thermodinamically very efficent and to save as much CO2 as possible. BDF solution allows pull up to 200TPD with its design, keeping the cold blanket technology for the batch feeding.

Equipment and accessories for the melting furnace

The studies and research developed over recent years combined with cutting-edge design tools are today able to guarantee stability and flexibility in the Furnaces management, for all types of production taking in consideration the strictly environmental regulations of reduction of CO2, NOx, SOx and all waste pollution related.

Next step, go to Condition working

and forehearth